The Vacuum Dewatered Flooring or VDF Flooring is a system for laying high quality concrete floors where the key is Dewatering of Concrete by Vacuum Process where in surplus water from the concrete is removed immediately after laying the concrete, using screed vibrator and levellers, there by reducing the water : cement ratio to the optimum level.

Advantages of Bull float

Bull Float is an instrument used to embed the course aggregate particles and to remove surface imperfection it also help to remove the excess bleed water from the concrete.

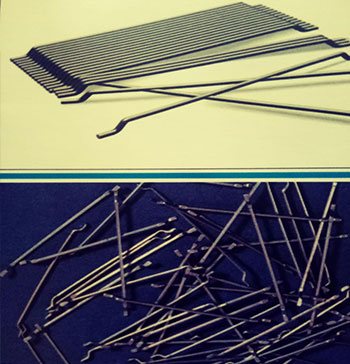

Steel Fibre Reinforced Concrete (SRC) is a concrete mixed with thin but high tensile steel wires drawn in a specific shape, having appropriately calculated aspect ratio (length to diameter) to reinforce the concrete for placing the ground floor slabs or even structural slabs, using appropriately calculated steel fibre dosage in the line with the load requirement of the project. BGSB certifies that SFRC flooring helps in improving crack resistance and impact resistance properties of concrete . SFRC flooring can be used with or without steel re-bar depending upon the load and performance requirement. If calculated right, it does helps in reducing the cost of construction by a certain percentage. Steel fibre comes in different shapes, sizes and forms (glued or non glued) differing from manufacturer to manufacturer and BGSB only recommends the best and has a strict multi point check criteria to choose the right product from the pre approved list of manufacturers. Having laid millions of square meters using Steel fibre (SFRC) and conventional Steel re-bar floors across India and Africa, BGSB claims to be a undisputed market leader in the industry of concrete flooring.

The groove will be marked in the construction joints, as well as in the perpendicular direction of the construction joints. Grooves are made using groove cutting machine with diamond wheel of 5mm width run with the help of 7.5hp motor The grooves are cleaned and dried using blowers. The groove is then filled with the backer rods and polysulphide sealent after sticking the masking tapes on either side of the grooves. Bitumen,Polyurethine sealent can also be filled in the grooves as per the requirement of the client.

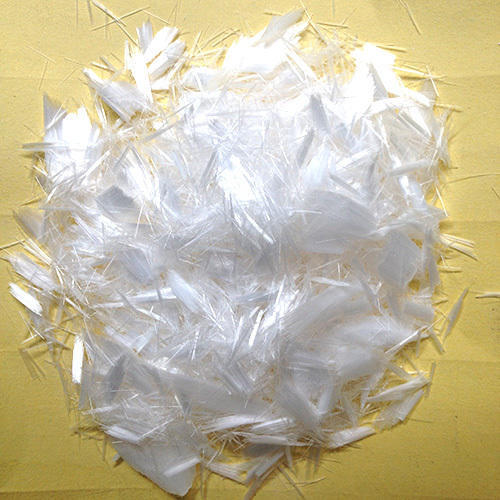

Glass fibers have an affinity for cementitious composites, high tensile strength and modulus of elasticity, are an ideal reinforcement for concrete, and are efficient at very early stages of the cracking process. Moreover, glass fibres density is similar to concrete, which allows a quick dispersion for very short mixing times, with minimum clumping risk and exceptionally low influence on workability. There are typically two major kinds of glass fibres. They are Micro and Macro Fibers used as per the requirement of the client.

Grano flooring is nothing but a final coat that are used over a cement concrete floor for finishing purposes, thus making the surface resistant to wear and tear caused due to abrasion action. Grano concrete is made of cement, sand and specially selected aggregates like basalt or limestone or quartzite.

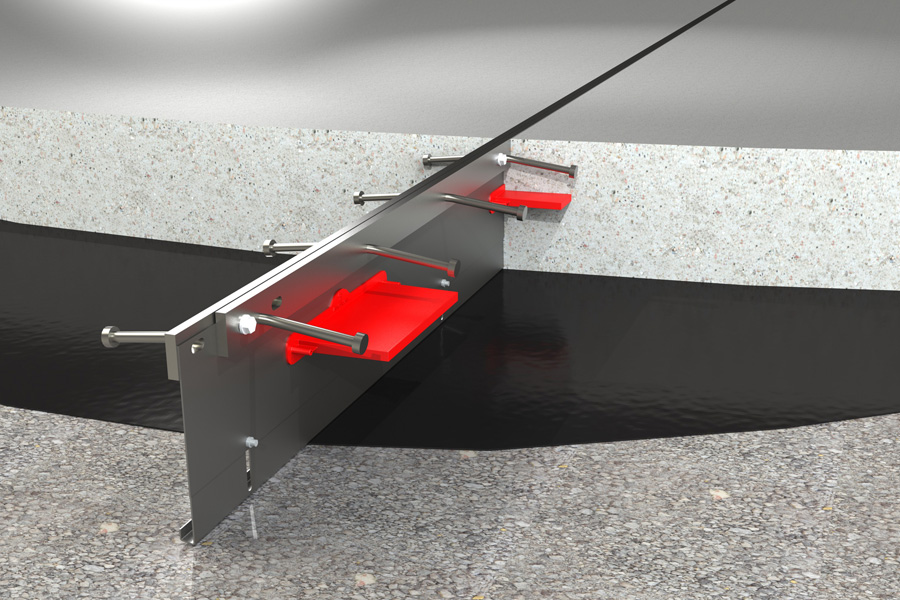

Armoured joints are used to create a boundary in which to contain a day's concrete pour. As the concrete sets and contracts, the two sides of the joint (held together with frangible rivet connectors) are gradually pulled apart horizontally.

Specific areas of use

1. Defined movement areas.

2. Transfer aisles, where vehicles cross joints at 90 degree

3. Doorway protection

4. Free movement areas

5. Jointless floors

6. Post – tensioned slabs

BGSB uses pure polyolefine based high grade PP fibre. This ensures absolute alkali resistance, not only on the surface but everywhere else too. The fibre material is chemically neutral (inert) and rot-proof, and its water absorption rate is virtually 0%

Here levels are fixed as per the required slope to drain water from the terrace and concrete is layed and levelled as per the levels fixed. Floaters are allowed to run over the concrete to give a rough finishing. 3’x3’ or 2’x2’ grooves are marked using thick twine.

Epoxy systems are based on a combination of resin and hardeners. When mixed together, the resin and hardener chemically react to form a rigid plastic material. The final material is strong, durable,resistant and bonds extremely well to most base layers. This epoxy flooring is used widely for machine shops, workshops and in pharma industries.

Polished concrete floor surface is made by a mechanical process of grinding and polishing with help of penetrating chemical and densifier to get rigid and highly polished surface.